In today’s competitive manufacturing landscape, an injection mold is more than just a tool—it’s a strategic asset that determines your product’s time-to-market, cost efficiency, and quality consistency. The steel that forms this asset is its very foundation. For Tier-1 automotive suppliers, appliance, furniture, and logistics manufacturers worldwide, navigating complex steel grades and volatile supply chains to make the optimal material choice is a core challenge demanding both technical expertise and commercial insight.

As a global injection mold supplier with over two decades of experience and an annual capacity of 4,000 sets, Kaihua Moulds has partnered with more than 280 clients worldwide. We understand that scientific steel selection isn’t about choosing the most expensive brand, but about finding the perfect balance between performance, cost, and risk throughout a project’s entire lifecycle. This article shares our practical approach to anchoring your project with this crucial “value cornerstone.”

Part 1: Beyond the Grade – A Product-Backward Selection Logic

At Kaihua Moulds, every discussion on steel begins with your final product. We believe selecting steel without context is aimless.

When “Perfect Appearance” is the Priority: For high-gloss grilles or door panels for brands like BMW and Audi, even microscopic surface flaws are unacceptable. Here, the steel’s ultimate polishability and absolute corrosion resistance are key. For such automotive plastic injection mold projects, we not only select high-purity mirror-grade steels like Germany’s Buderus 2738 but also implement a “zero-dust” standard throughout the entire manufacturing process, protecting the final gloss from texturing to assembly.

When “Millions of Cycles” is the Daily Norm: For molds producing logistics containers or automotive engine components, the challenge is wear and fatigue over millions of cycles. In mass production projects for Ford or Nissan, we prioritize steel toughness. This is like giving the mold an “anti-fatigue” gene, ensuring cavity stability and preventing premature cracking, even under long-term, high-frequency impact, supporting stable production line operation.

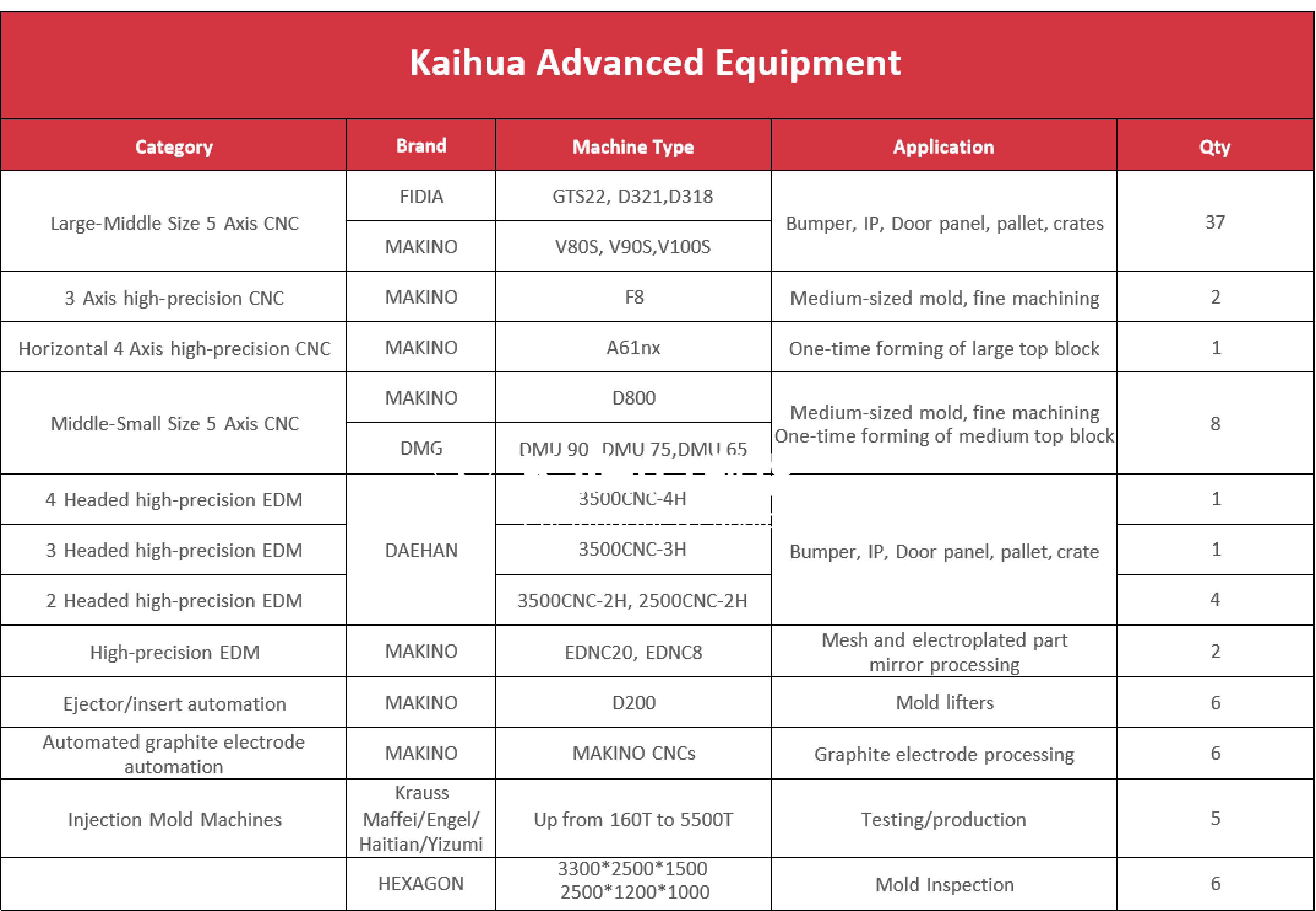

When “Large & Complex” Must Meet “Cost Efficiency”: For large molds like automotive dashboards or bumpers, the steel’s machinability and hardenability are critical to project success and budget. Serving clients like Mercedes-Benz and Great Wall Motors, we prioritize pre-hardened steels co-developed with top mills like Baosteel. These steels perform exceptionally on our Makino 5-axis machining centers, ensuring uniform properties from the core to the surface of large mold bases. This not only shortens lead times but also significantly reduces risks from performance inconsistency.

Part 2: Calculating the “Total Cost” – Real-World Cases with a Holistic View

While price often dominates procurement meetings, Kaihua Moulds focuses on “Total Cost of Ownership” during joint project reviews with clients. Real cases speak louder than theory.

We once worked with a leading appliance brand on a new appliance panel mold facing fierce price competition during initial bidding. A supplier offered an attractive low-cost plan using “performance-equivalent” alternative steel. However, based on simulations from our historical database, our team advised the client that the alternative steel could lead to higher wear rates during long-term production, potentially causing earlier maintenance and about 15% more downtime risk. We recommended slightly higher initial investment in more wear-resistant premium steel.

The client accepted our proposal. The mold not only achieved the desired surface finish but also maintained excellent stability over three years of mass production, avoiding most unplanned downtime. A post-project review showed that while the initial mold investment was higher, the combined savings from reduced maintenance, avoided production losses, and the market gains from a secured launch timeline resulted in a far greater total return.

This case reveals a crucial truth: the initial price difference is often just the tip of the iceberg. Hidden beneath are processing waste, maintenance costs, downtime risks, and even product reputation—the true determinants of a project’s final profitability. Leveraging our vast database of material applications, Kaihua Moulds helps clients see the full picture of this “cost iceberg” from the very start.

Part 3: The Foundation of Trust – A Closed-Loop Quality System

Our steel confidence comes from a rigorous five-step verification process:

Verified Sources: We work deeply with leading mills like Buderus, ASSAB, and Baosteel.

Composition Check: We verify each shipment’s chemical makeup using advanced spectrometry.

Internal Inspection: Ultrasound testing detects hidden defects in critical mold bases.

Precision Processing: We match each steel grade with optimized heat treatment and machining parameters.

Proven Results:Our database is built upon the accumulation of performance insights drawn from extensive hands-on project experience.

Looking Ahead: Material Intelligence for the Future

As new energy vehicles demand more complex parts and smart home devices require superior surface quality, mold steel selection is becoming more precise and customized. Kaihua Moulds is integrating digital tracking for material performance lifecycle management and utilizing 5G+AR remote service systems to optimize our global clients’ mold status and maintenance plans in real-time.

We firmly believe that every prudent, scientific steel choice is a commitment to the product’s life and a respect for the craft of manufacturing itself. It is not merely a technical decision but a wisdom of long-term development.

Get Your Customized Material Analysis

If you are facing material selection for a new project or looking to optimize the lifespan of existing tooling, the technical team at Kaihua Moulds can provide scenario-based steel selection and Total Cost of Ownership analysis. Welcome to contact us via our website for a dedicated consultation.

Media Contact

Company Name: ZHEJIANG KAIHUA MOULDS CO.,LTD

Email: Send Email

Country: China

Website: https://www.kaihuamoulds.com/