DAYTON, OH – November 20, 2025 – In a significant development for advanced manufacturing, Bullen Ultrasonics, a leader in ultrasonic machining, has been honored with the prestigious 2025 Innovator of the Year award by the Dayton Business Journal. The recognition, announced on November 18, 2025, celebrates Bullen's groundbreaking MicroLucent technology, an ultrafine laser machining platform poised to revolutionize the precision fabrication of transparent and delicate materials. This breakthrough, coupled with Bullen's aggressive embrace of Industry 4.0 principles and in-house automation, marks a pivotal moment, enabling the creation of next-generation components crucial for the relentless advancement of artificial intelligence and high-tech industries worldwide.

technology, an ultrafine laser machining platform poised to revolutionize the precision fabrication of transparent and delicate materials. This breakthrough, coupled with Bullen's aggressive embrace of Industry 4.0 principles and in-house automation, marks a pivotal moment, enabling the creation of next-generation components crucial for the relentless advancement of artificial intelligence and high-tech industries worldwide.

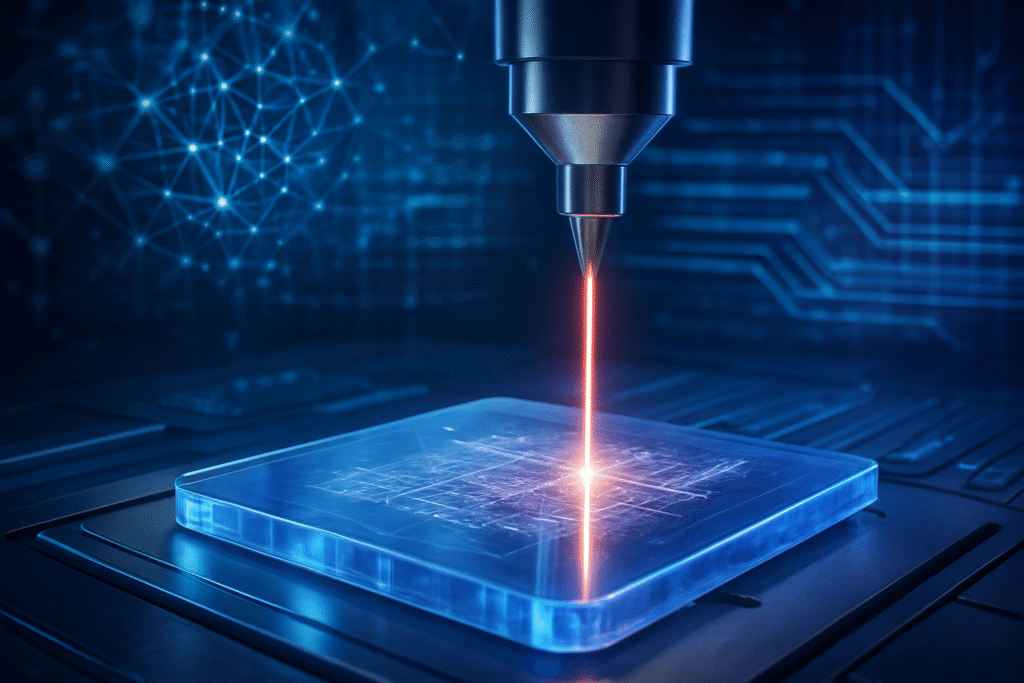

MicroLucent stands out for its ability to achieve micron-level precision without the damaging heat-affected zones (HAZ) typically associated with traditional laser machining or electrical discharge machining (EDM). This non-thermal process preserves the structural integrity and optical quality of materials like quartz, specialty glasses, and sapphire, opening new frontiers for component design and manufacturing. As the demand for sophisticated hardware to power AI continues to surge, technologies like MicroLucent

stands out for its ability to achieve micron-level precision without the damaging heat-affected zones (HAZ) typically associated with traditional laser machining or electrical discharge machining (EDM). This non-thermal process preserves the structural integrity and optical quality of materials like quartz, specialty glasses, and sapphire, opening new frontiers for component design and manufacturing. As the demand for sophisticated hardware to power AI continues to surge, technologies like MicroLucent become indispensable, laying the foundational physical infrastructure for increasingly complex and powerful AI systems.

become indispensable, laying the foundational physical infrastructure for increasingly complex and powerful AI systems.

Unpacking the MicroLucent Advantage: Precision Beyond Compare

Advantage: Precision Beyond Compare

Bullen Ultrasonics' MicroLucent technology represents a significant leap forward in precision manufacturing, offering a proprietary ultrafine laser machining platform specifically engineered for the most challenging materials. This innovative system can precisely machine a diverse array of features, including intricate round, rectangular, and irregular-shaped holes, slots, and cavities. Furthermore, it excels at enabling blind cuts, complex internal geometries, and precision machining of both outside and inside diameters on transparent substrates.

technology represents a significant leap forward in precision manufacturing, offering a proprietary ultrafine laser machining platform specifically engineered for the most challenging materials. This innovative system can precisely machine a diverse array of features, including intricate round, rectangular, and irregular-shaped holes, slots, and cavities. Furthermore, it excels at enabling blind cuts, complex internal geometries, and precision machining of both outside and inside diameters on transparent substrates.

What sets MicroLucent apart from previous approaches is its unique non-thermal processing method. Unlike conventional laser machining, which often introduces thermal stress and micro-cracks, or EDM, which is limited by material conductivity and can leave recast layers, MicroLucent

apart from previous approaches is its unique non-thermal processing method. Unlike conventional laser machining, which often introduces thermal stress and micro-cracks, or EDM, which is limited by material conductivity and can leave recast layers, MicroLucent operates without generating heat-affected zones. This preserves the intrinsic material properties, preventing changes in refractive index, stress points, or structural degradation. The result is superior material integrity, near-zero depth of damage, and components that meet the most stringent performance requirements for optical clarity and mechanical strength. This level of precision and material preservation is critical for the delicate components found in advanced AI hardware, where even microscopic imperfections can impact performance.

operates without generating heat-affected zones. This preserves the intrinsic material properties, preventing changes in refractive index, stress points, or structural degradation. The result is superior material integrity, near-zero depth of damage, and components that meet the most stringent performance requirements for optical clarity and mechanical strength. This level of precision and material preservation is critical for the delicate components found in advanced AI hardware, where even microscopic imperfections can impact performance.

Initial reactions from the AI research community and industry experts, though not explicitly detailed, can be inferred from the award itself and the technology's capabilities. The ability to produce high-quality, ultra-precise components from traditionally difficult materials at high throughput and without significant non-recurring engineering costs suggests a strong positive reception, particularly in sectors where material integrity and miniaturization are paramount for AI applications.

Strategic Implications for the AI Ecosystem

The advent of MicroLucent technology carries profound implications for AI companies, tech giants, and burgeoning startups across the globe. Companies heavily invested in the development of cutting-edge AI hardware stand to benefit immensely. This includes manufacturers of advanced semiconductors (e.g., for quartz semiconductor gas distribution plates), developers of sophisticated optical sensors for autonomous vehicles and robotics, creators of high-precision medical devices with integrated AI capabilities, and innovators in the defense and aerospace sectors requiring robust, transparent components for AI-driven systems.

technology carries profound implications for AI companies, tech giants, and burgeoning startups across the globe. Companies heavily invested in the development of cutting-edge AI hardware stand to benefit immensely. This includes manufacturers of advanced semiconductors (e.g., for quartz semiconductor gas distribution plates), developers of sophisticated optical sensors for autonomous vehicles and robotics, creators of high-precision medical devices with integrated AI capabilities, and innovators in the defense and aerospace sectors requiring robust, transparent components for AI-driven systems.

The competitive landscape for major AI labs and tech companies will undoubtedly be influenced. Those who can quickly adopt and integrate MicroLucent -enabled components into their product lines will gain a significant strategic advantage. This technology could accelerate the development of more powerful, compact, and reliable AI processors, specialized neural network accelerators, and highly sensitive sensor arrays. For instance, enhanced precision in optical components could lead to breakthroughs in AI vision systems, while superior machining of transparent substrates could enable next-generation display technologies or more efficient cooling solutions for AI data centers.

-enabled components into their product lines will gain a significant strategic advantage. This technology could accelerate the development of more powerful, compact, and reliable AI processors, specialized neural network accelerators, and highly sensitive sensor arrays. For instance, enhanced precision in optical components could lead to breakthroughs in AI vision systems, while superior machining of transparent substrates could enable next-generation display technologies or more efficient cooling solutions for AI data centers.

Potential disruption to existing products or services is also on the horizon. Traditional precision machining providers that cannot match MicroLucent 's capabilities in terms of material compatibility, precision, and freedom from HAZ may find their offerings less competitive for high-end applications. Bullen Ultrasonics (BULLEN ULTRASONICS, Private) itself is strategically positioned as a critical enabler for the next wave of AI hardware innovation, offering a foundational technology that underlies the physical evolution of artificial intelligence.

's capabilities in terms of material compatibility, precision, and freedom from HAZ may find their offerings less competitive for high-end applications. Bullen Ultrasonics (BULLEN ULTRASONICS, Private) itself is strategically positioned as a critical enabler for the next wave of AI hardware innovation, offering a foundational technology that underlies the physical evolution of artificial intelligence.

MicroLucent in the Broader AI Landscape: A Foundational Enabler

in the Broader AI Landscape: A Foundational Enabler

MicroLucent technology, while not an AI system itself, is a quintessential example of how advancements in manufacturing and materials science are intrinsically linked to the progress of artificial intelligence. It fits squarely into the broader AI landscape by serving as a foundational enabler, allowing for the physical realization of increasingly complex and demanding AI hardware. The precision and material integrity offered by MicroLucent

technology, while not an AI system itself, is a quintessential example of how advancements in manufacturing and materials science are intrinsically linked to the progress of artificial intelligence. It fits squarely into the broader AI landscape by serving as a foundational enabler, allowing for the physical realization of increasingly complex and demanding AI hardware. The precision and material integrity offered by MicroLucent are critical for developing the next generation of AI processors, high-fidelity sensors, advanced optics for machine vision, and specialized substrates for emerging computing paradigms like quantum and neuromorphic computing.

are critical for developing the next generation of AI processors, high-fidelity sensors, advanced optics for machine vision, and specialized substrates for emerging computing paradigms like quantum and neuromorphic computing.

The impacts are far-reaching: it facilitates miniaturization, improves component reliability, and accelerates development cycles for AI-driven products. By enabling the creation of components that were previously difficult or impossible to manufacture with such precision, MicroLucent removes a significant bottleneck in hardware innovation. Potential concerns are minimal from an AI ethics standpoint, as the technology is a manufacturing process. However, the specialized nature of the equipment and the expertise required to leverage it might create a demand for new skill sets in the advanced manufacturing workforce.

removes a significant bottleneck in hardware innovation. Potential concerns are minimal from an AI ethics standpoint, as the technology is a manufacturing process. However, the specialized nature of the equipment and the expertise required to leverage it might create a demand for new skill sets in the advanced manufacturing workforce.

Comparing this to previous AI milestones, MicroLucent is akin to the advancements in photolithography that enabled the semiconductor revolution, which in turn provided the computational backbone for modern AI. Just as better chip manufacturing led to more powerful processors, MicroLucent

is akin to the advancements in photolithography that enabled the semiconductor revolution, which in turn provided the computational backbone for modern AI. Just as better chip manufacturing led to more powerful processors, MicroLucent is poised to enable more sophisticated and robust physical components that will empower future AI systems. It represents a critical step in bridging the gap between theoretical AI breakthroughs and their practical, high-performance implementations.

is poised to enable more sophisticated and robust physical components that will empower future AI systems. It represents a critical step in bridging the gap between theoretical AI breakthroughs and their practical, high-performance implementations.

The Horizon: Intelligent Manufacturing and Future AI Applications

Looking ahead, the trajectory of MicroLucent technology is deeply intertwined with the ongoing evolution of artificial intelligence and advanced automation. Bullen Ultrasonics has already demonstrated its commitment to Industry 4.0 principles, integrating fully automated robotic machining cells designed in-house. This paves the way for the direct integration of AI into the manufacturing process itself.

technology is deeply intertwined with the ongoing evolution of artificial intelligence and advanced automation. Bullen Ultrasonics has already demonstrated its commitment to Industry 4.0 principles, integrating fully automated robotic machining cells designed in-house. This paves the way for the direct integration of AI into the manufacturing process itself.

Expected near-term developments include the deployment of AI for predictive maintenance, allowing MicroLucent systems to analyze machine data and anticipate potential failures before they occur, thereby maximizing uptime and efficiency. Long-term, Bullen envisions adaptive machining, where AI algorithms make real-time adjustments to cutting paths, speeds, and tooling based on live feedback, optimizing precision and throughput autonomously. AI-driven process optimization will further enhance machine efficiency, schedule optimization, and overall production processes.

systems to analyze machine data and anticipate potential failures before they occur, thereby maximizing uptime and efficiency. Long-term, Bullen envisions adaptive machining, where AI algorithms make real-time adjustments to cutting paths, speeds, and tooling based on live feedback, optimizing precision and throughput autonomously. AI-driven process optimization will further enhance machine efficiency, schedule optimization, and overall production processes.

The potential applications and use cases on the horizon are vast. We can expect to see MicroLucent facilitating the creation of even more complex micro-structures for advanced photonics, which are critical for optical AI and high-speed data transfer. It will enable next-generation medical implants with seamlessly integrated, highly precise sensors for continuous health monitoring, and contribute to the development of high-performance transparent displays for augmented reality and AI interfaces. Furthermore, more robust and lightweight components for aerospace and defense, including those for space-based AI systems, will become feasible.

facilitating the creation of even more complex micro-structures for advanced photonics, which are critical for optical AI and high-speed data transfer. It will enable next-generation medical implants with seamlessly integrated, highly precise sensors for continuous health monitoring, and contribute to the development of high-performance transparent displays for augmented reality and AI interfaces. Furthermore, more robust and lightweight components for aerospace and defense, including those for space-based AI systems, will become feasible.

Challenges that need to be addressed include the continued development of sophisticated AI algorithms tailored for manufacturing environments, ensuring seamless integration with existing factory ecosystems, and fostering a workforce capable of operating and maintaining these increasingly intelligent systems. Experts predict a continued convergence of advanced manufacturing techniques with AI and automation, leading to unprecedented levels of precision, efficiency, and material utilization, ultimately accelerating the pace of AI innovation across all sectors.

A New Era of Precision Enabling AI's Ascent

Bullen Ultrasonics' recognition as the 2025 Innovator of the Year for its MicroLucent technology represents a monumental achievement, signaling a new era in precision manufacturing. The key takeaway is clear: MicroLucent

technology represents a monumental achievement, signaling a new era in precision manufacturing. The key takeaway is clear: MicroLucent is not just an incremental improvement but a breakthrough, enabling the creation of critical, high-precision components from delicate materials with unmatched integrity and efficiency. This foundational technology is poised to significantly accelerate hardware innovation for artificial intelligence, underpinning the development of more powerful, compact, and reliable AI systems.

is not just an incremental improvement but a breakthrough, enabling the creation of critical, high-precision components from delicate materials with unmatched integrity and efficiency. This foundational technology is poised to significantly accelerate hardware innovation for artificial intelligence, underpinning the development of more powerful, compact, and reliable AI systems.

In the grand tapestry of AI history, MicroLucent will be remembered as a pivotal enabling technology. It stands alongside other critical advancements in materials science and manufacturing that have historically paved the way for technological revolutions. By removing previous manufacturing bottlenecks, it empowers AI researchers and developers to push the boundaries of what's possible, from advanced sensors and optics to next-generation processors and beyond.

will be remembered as a pivotal enabling technology. It stands alongside other critical advancements in materials science and manufacturing that have historically paved the way for technological revolutions. By removing previous manufacturing bottlenecks, it empowers AI researchers and developers to push the boundaries of what's possible, from advanced sensors and optics to next-generation processors and beyond.

The long-term impact of MicroLucent will be felt across virtually every industry touched by AI, fostering greater innovation, driving down costs through improved yields, and enabling the creation of products previously confined to the realm of science fiction. As we move forward, what to watch for in the coming weeks and months includes further announcements from Bullen Ultrasonics regarding the integration of AI into their manufacturing processes, and the increasing adoption of MicroLucent

will be felt across virtually every industry touched by AI, fostering greater innovation, driving down costs through improved yields, and enabling the creation of products previously confined to the realm of science fiction. As we move forward, what to watch for in the coming weeks and months includes further announcements from Bullen Ultrasonics regarding the integration of AI into their manufacturing processes, and the increasing adoption of MicroLucent -enabled components in the next wave of AI products and solutions. This is a testament to how breakthroughs in one field can profoundly impact and accelerate progress in another, particularly in the interconnected world of advanced technology and artificial intelligence.

-enabled components in the next wave of AI products and solutions. This is a testament to how breakthroughs in one field can profoundly impact and accelerate progress in another, particularly in the interconnected world of advanced technology and artificial intelligence.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.